The stronger the cover, the safer the cover. No company builds in more exclusive design and

manufacturing features to ensure the strength and performance of its automatic

covers than Coverstar.

Most automatic cover manufacturers sew webbing material

wrapped around rope to the cover. With this method, the webbing often fails

before the fabric does. Coverstar uses

an exclusive, patented process to heat seal webbing around a polymer bead and

weld it to the cover in one step.

Independent lab tests show Coverstar’s webbing to be over twice as

strong as competitive webbing sewn to a cover.

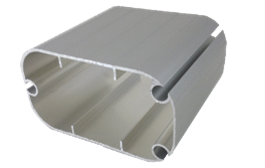

Our unique mechanism is engineered with heavy-duty components

and with ropes and pulleys that are stronger than any others used in the

industry. The extreme precision of the

machined and laser cut parts allows for smooth operation and many years of

hassle-free use.

Coverstar Motors

PowerFlex Ropes

Coverstar motors are completely sealed, using a proprietary

method to prevent water damage. Other less

reliable means of water protection could mean an expensive motor repair.

PowerFlex Ropes

PowerFlex Ropes come with a two year no-break warranty.

The torque limiter is adjustable to protect the motorized

mechanism form too much stress.

Durable Fabric

Coverstar fabric is made using an advanced vinyl formulation

and superior fabrication methods, which make it the top of the line.

For more information on these and other Coverstar features, go to www.coverstar.com.

For more information on these and other Coverstar features, go to www.coverstar.com.